NA LAKO HANA

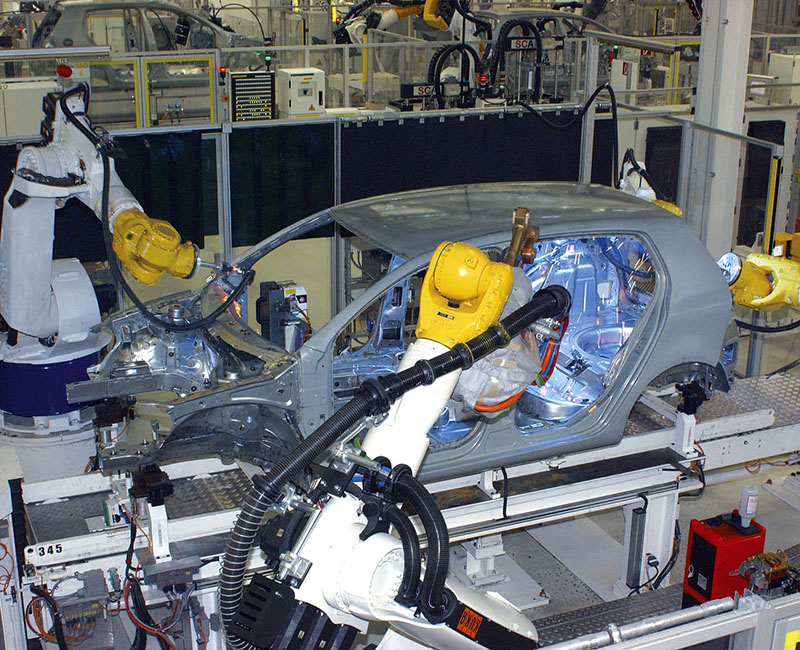

ʻOiai ʻo ka hoʻoheheʻe ʻana a me ke kuʻi ʻana he mau hana kahiko no ka hoʻohui ʻana i nā metala, ua kūpono mau lākou i nā kaʻina hana automated hou.Ma kahi o ka hāmare a ka ʻeleʻele, hoʻohana nā ʻoihana o kēia wā i nā ʻano like ʻole e like me nā kukuna laser no ka hoʻohui ʻana i nā mea.

Hiki ke ʻike ʻia nā ʻano hana kuʻiʻo kahiko loa i ka makahiki Bronze, ʻoi aku ma mua o 2.000 mau makahiki i hala, i loko o ka pahu i hana ʻia i ke gula.I ka Iron Age, ua aʻo ke kanaka e wili i ka hao a i ka Middle Ages, hoʻohana mau ka poʻe ʻeleʻele i ka hāmare.Ua hana ʻia ka welding hou i ka makahiki 19thkenekulia a ua ʻike i kekahi mau mea hou a me nā ʻenehana hou.ʻO ka mea hou loa ka hoʻokomo ʻana o ka laser i nā kaʻina hana welding.

Hiki i nā kukuna laser ke hoʻoheheʻe a hoʻopau i nā metala me ka maikaʻi loa a me ka pololei loa.No laila ʻo ka hui ʻana i nā lau lahilahi ke kahua o ka laser.ʻO ke kuʻi ʻana a i ʻole ke kuʻi ʻana, ʻokoʻa loa nā hili, pololei a paʻa.ʻO ka ikehu kiʻekiʻe i hoʻohana ʻia ma nā wahi kikoʻī e hiki ai i ka wikiwiki o ka wiliwili.Eia naʻe, pono kēia hana i ka mana kiʻekiʻe a me ke kūlana o ka laser.

Loaʻa nā ʻano hana like ʻole no ka soldering automated a i ʻole ka welding.Inā kūʻai, induction brazing a i ʻole welding laser - hāʻawi pinepine ʻia ka weld filler metala e ka uea.Eia naʻe, ʻo kēia kahi e waiho ai ka pilikia.Pono ka ʻōnaehana e hāʻawi mau i ka lōʻihi o ka hoʻopiha piha ʻana i ka wahi kūpono, akā me ka ʻole o ka hoʻokuʻu ʻana a i ʻole ke kulou ʻana i ka uea i ke kaʻina hana.ʻO ka mea hānai uea maʻalahi e alakaʻi ʻia e kahi micromotor i hoʻopaʻa ʻia he noi nui ʻē aʻe no kā mākou ʻōnaehana hoʻokele hilinaʻi loa.

ʻAʻole paha ʻo kā mākou kaʻa stepper maikaʻi loa, ka mīkini DC me nā encoders kiʻekiʻe a i ʻole ka mīkini brushless no nā hana kūlana kiʻekiʻe - me ka waihona HT-GEAR ākea a nui hoʻi mākou e hoʻoikaika nei e ʻimi i ka hopena hoʻokele maikaʻi loa e kūpono i nā pono o kāu. hoʻopili maikaʻi loa.

ʻO ka pololei a me ka hilinaʻi kiʻekiʻe

Ke kūlana hoʻoikaika kiʻekiʻe