42mm Nema 17 DC Brush Gear Motor 24V 5000RPM

Specifications

| Product Name | Dc Peniculus Gear Motor |

| Rated Voltage | 24 V |

| Motor Speed | 5000 RPM |

| Rated Speed | 200 RPM |

| Armen Torque | ≥10 Nm |

| Max Radial Load | ≤120N (10mm Frons Flange) |

| Reductio Ratio | ≤1.5 |

| Telum Axial Load | ≤80N |

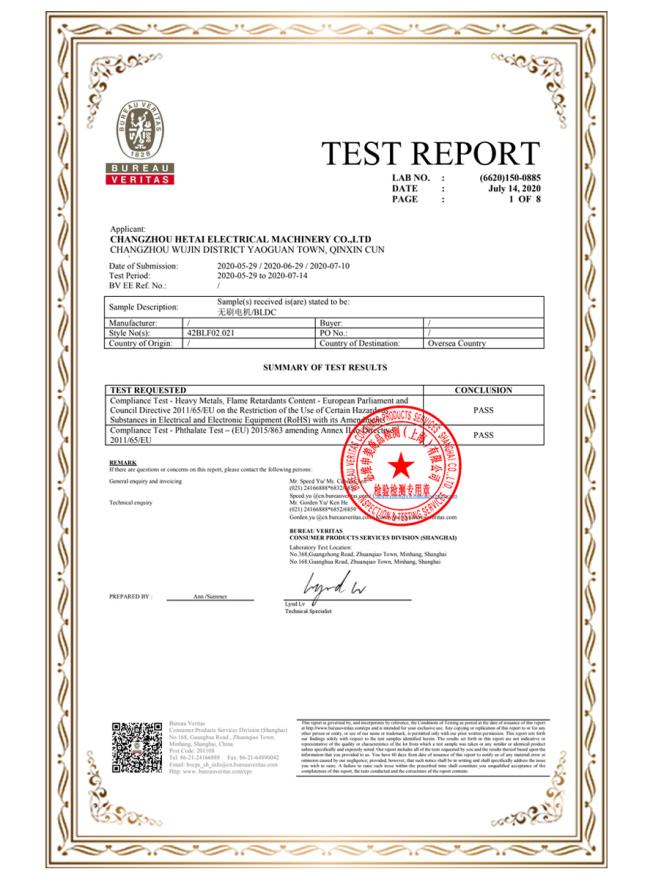

| Cetification | CE ROHS ISO |

| Praesidium Level | IP40 |

depictio producti

42mm Nema 17 DC Brush Gear Motor 24V 5000RPM

| Specificationes cum PLANETARIA APPARATUS | ||

| Rated Speed | RPM | 200 |

| Rated Voltage | V | 24 |

| Motor Speed | Rpm | 5000 |

| REDUCTIO RATIO |

| 25:1 |

Exigua peniculus dc calces motoriis utens calcaribus anni praebent utilitates in applicationibus cum limite maximo currenti, ubi infimae friction initus et efficientia alta sunt essentialia.Coniunctio 42mm pulveris metallurgiae cistae calces cum micro penicilli DC motoribus praebet unam solutionem officinarum integratam postulandi, applicationes altae torques.Ob stimulum compositorum calceorum dispositio, micro dc calces motoris output per eundem axem ac motor praebet.Consilium proprium penicilli nostri DC motorum calceorum consequitur in altiore efficacia meliore et strepitu inferiori, amplis applicationibus adiuvando incluso soleatus medicorum, securitatis et accessus et ostium aperientis.Vel, praecipuae utilitates motorum planetarum Hetai parvae dc calces motorum sunt magni aestimandi torques et reductionis ratio per agmen phaleris altum, adhibens qualitatem materiae compositae.

42mm Pulvis Metallurgy

| Praesent materia | Attento output | Radialis onus (10mm e LABIUM) N | Telum axiale onus (N) | Shaft press-fit vis max (N) | Radialis fabula scapi (mm) | Mitte fabula scapi (mm) | Backlash in nullo onus (°) |

| Metallurg pulvis | Sleeve Bearings | ≤120 | ≤90 | ≤500 | ≤0.03 | ≤0.1 | ≤1.5 |

| Reductio ratio | (Nm) Rated tolerantia torque | (Nm) Max tolerantia momentanea torque | efficientiam% | L(mm)Longitudo | (G) Pondus | Multis impedimenta calces |

| 1/4 | 1.0 | 3.0 | 81% | 32.5 | 170 | 1 |

| 1/6 | ||||||

| 1/15 | 4.0 | 12 | 72% | 46.3 | 207 | 2 |

| 1/18 | ||||||

| 1/25 | ||||||

| 1/36 | ||||||

| 1/54 | 8.0

| 25

| 65%

| 60.1

| 267

| 3 |

| 1/65 | ||||||

| 1/90 | ||||||

| 1/112 | ||||||

| 1/155 | ||||||

| 1/216 | 10 | 30 | 65% | 60.1 | 267 | 3 |

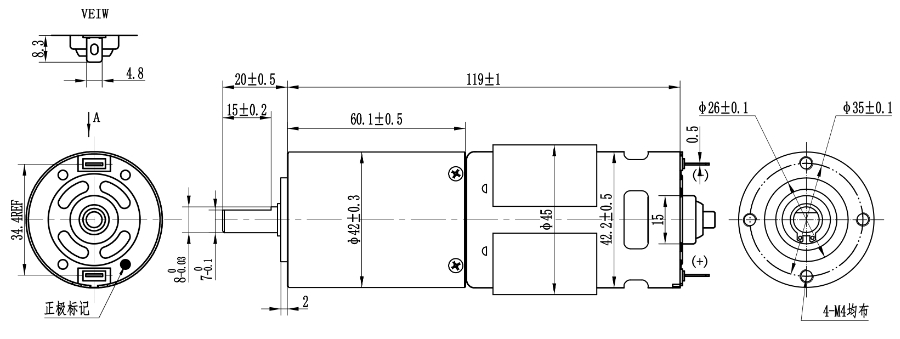

Mechanica Dimensio

Forum Range

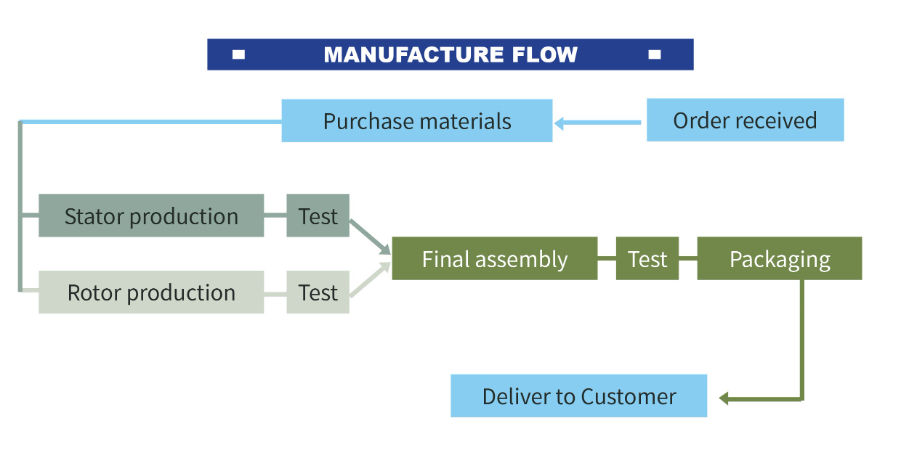

Processus productionis

Conventus Line

Productio apparatu