COMPACT INDUSTRIAL ROBOTS

The miniaturization of mechanical, electrical and electronic components is one of the key trends dominating research and development activities within the area of miniature drive technology. To be able to measure structures in the sub-micrometer range reliable, specialist know-how is essential; simply adopting a downsized standard solution from the „big world“ is not an option. Small yet high-powered motors from HT-GEAR are perfectly capable of exploiting new opportunities in automation technology.

Ultra-fine motion control in the production of high-purity crystals and in focusing, scanning, adjustment, inspection and measurement tasks in the sub-μm range demands highly accurate, reproducible movements. The conventional approach to this is to run the object being measured past a measuring probe or actuator on a linear positioner. Piezo drives are known for their capacity to deliver ultra-fine step widths, but unfortunately their dynamism is insufficient to transport the payload into the work area. The traditional solution means minutes of approach work to reach the measuring position. But long setup times cost money. A patented solution for this dilemma uses a geared HT-GEAR DC motor for fast transport over long distances. The fine adjustment is being handled by a high precision piezo motor.

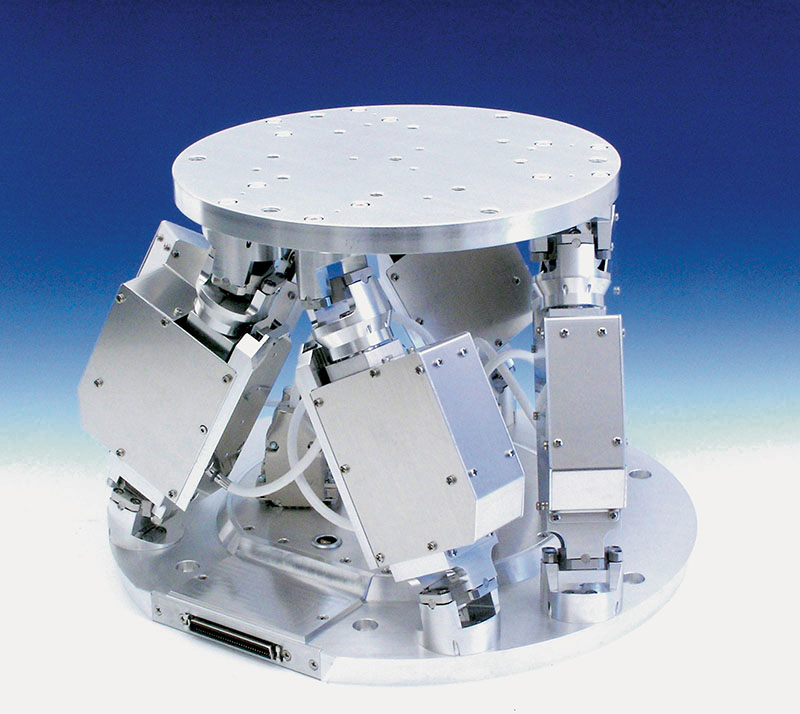

Another example of a compact industrial robotic positioning system where HT-GEAR is driving miniaturization is the so called Hexapod. These systems are based on six high-resolution actuators that control a single platform. Instead of hydraulic drives, hexapods are powered by high-precision drive spindles and precisely controllable electrical motors. In order to achieve the high positioning accuracy required, the drive systems must also work as backlash-free as possible over the complete operating period.

When it comes to such and other challenging applications, HT-GEAR’s standard range of DC precision motors is always primed for action. The self-supporting, ironless rotor coil with a skew-wound design and precious metal commutation provides very favorable preconditions for such areas of application. For example ensuring immediate and high-torque start-up of the DC motors after a voltage is applied. The small, light-weight DC drives furthermore work reliably in adverse environmental conditions.

Ultra-fine motion control

Highly accurate, reproducible movements

Zero backlash