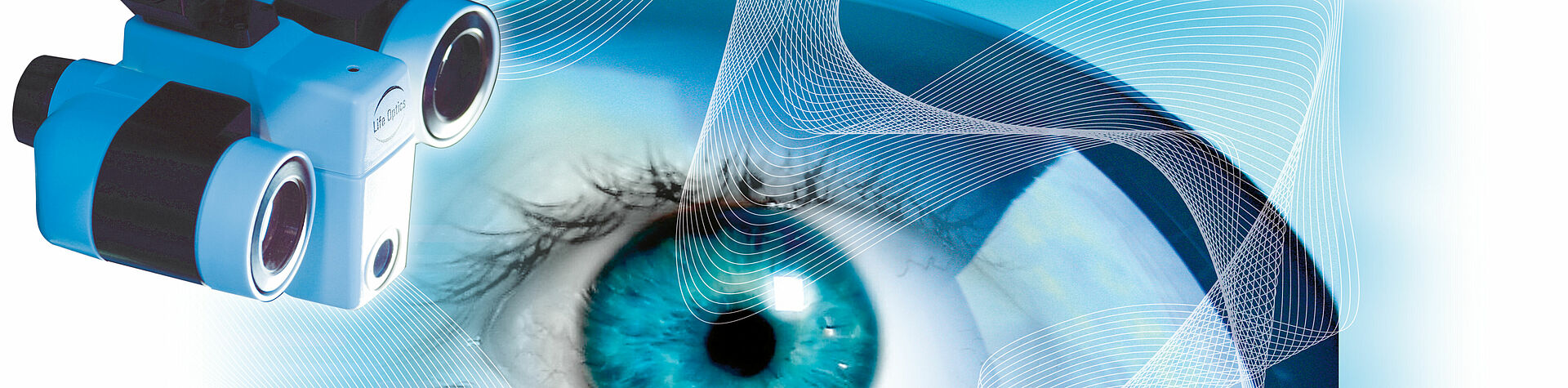

OPTICS

When a free kick comes in the last minute of extra time, it is all or nothing for soccer fans. The camera must capture even the smallest movement. However, it is literally a matter of life and death when people need saving from burning buildings. Less dramatic but just as exciting is research involving the smallest and largest objects in the universe using microscopes and telescopes or femtosecond lasers. In all these situations, the micromotors from HT-GEAR ensure the perfect positioning of the optical components.

Optics and precision have belonged together ever since the first glass lenses were ground. Strengthening or focusing light, or "stimulating" it to create a laser beam, requires highly precise mechanical devices. In modern optical devices and systems, components are moved using motors. Often, these motors are very sophisticated structures that are housed in the confined interior of a microscope or a night-vision device, for example. The demands placed on these drives could hardly be higher: The utmost precision when carrying out the movements is only the minimum requirement. It also goes without saying that sufficient power must be compressed down into the smallest dimensions. In addition, the motors must produce only absolutely unavoidable minimal vibrations while running. They must generate and emit virtually no heat because any change in temperature could alter the precisely set angles and distances. In battery-operated devices, they must run on the smallest possible power supply and create as little audible noise as possible.

Since they meet these requirements, motors and drive units from HT-GEAR are used in numerous and highly diverse optical applications. Their high power density means that they fit in an extremely small device housing, while their unmatched speed control minimizes vibrations and noise generation. They are unbeatable in terms of energy efficiency and deliver the utmost precision when it comes to alignment and orientation movements.

Highest precision and reliability

Low weight

Extremely long operational lifetimes