PUMPS

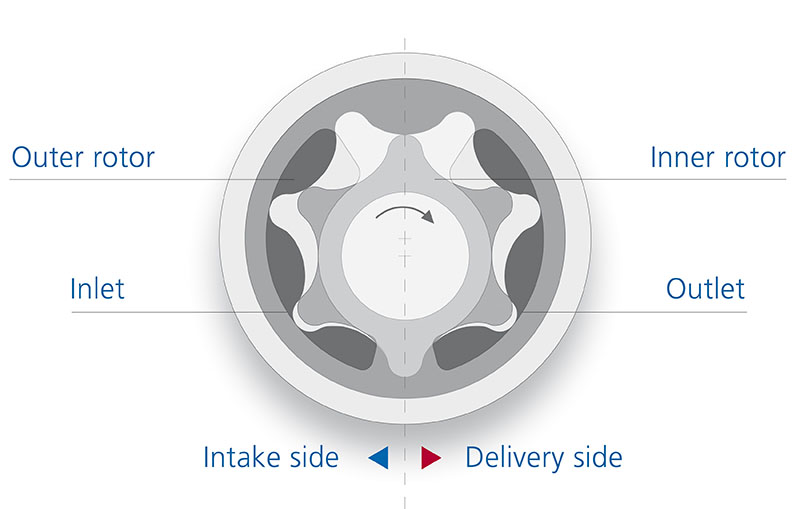

Dosing according to volume has been proven to be the simplest and most flexible method in practice, since the substance (soldering paste, adhesive, lubricant, potting material or sealant) that needs to be delivered “only” needs to be moved back to the dosing tip by pumps delivering uniform quantities. Precision dispensers should also be as compact as possible so that they can be easily integrated into the production systems. They are therefore reliant upon small, powerful drives that provide the best possible dynamics and can be precisely controlled. In other words: HT-GEAR!

The spread of miniaturization in automation is leading to ever increasing demands for optimum dosage of the tiniest quantities. Whether in electronics or micromechanical engineering: solder pastes, adhesives, lubricants, potting and sealing compounds have to be applied precisely where they are needed, in exactly the right dosage, with no spillage or dripping. Automatically dosing small quantities in a targeted way is no trivial matter. In fact, it demands detailed know-how and innovative strength.

Miniature drives are the most suitable power source for high precision dosing pumps. They deliver high performance in a compact design, and are precisely controllable – both attributes which are essential to a dosage unit.

Our HT-GEAR portfolio offers you a wide range of suitable drive solutions, depending on your specific requirements. With a combination of DC motor, a high resolution encoder and a precision gearhead, simple pulse-width regulation and direction of rotation changes are possible. The encoders and planetary gearheads in motor diameter allow for very slim designs, even for higher feed pressures and therefore higher torque requirements.

When it comes to our electronically commutated DC motors, our solutions with integrated speed controllers offer a next level of compactness. In the configuration with our 22mm BX4 motors, motor-adapted variable speed control is guaranteed by a speed controller that has the same diameter as the motor and is mounted to the rear of the motor. The brushless design furthermore enhances the service life and reliability of the drive.

High performance in a compact design

Precisely controllable

High reliability and long service life